- Startseite

- Produkte

- Starre und elastische Kupplungen

- Beam Kupplungen

- LK2-4 Beam Kupplung - Klemmbefestigung

LK2-4 Beam Kupplung - Klemmbefestigung

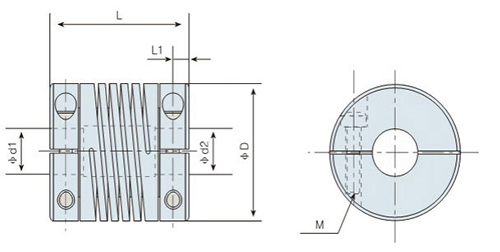

DimensionenHinweis:Das Modell mit S besteht aus Edelstahl und das Modell ohne S besteht aus Aluminiumlegierung

Informieren Sie uns über das Modell und φd1φd2 ihres gewünschten Produktes bitte.

| Modell | φd1φd2 Max. Bohrungsdurchmesser | φD | L | L1 | M | Anzugsdrehmoment ( N.M ) |

| LK2-C075-M SLK2-C075-M | 6.35 | 19.1 | 22.9 | 3.10 | M2.5 | 0.8 |

| LK2-C100-M SLK2-C100-M | 10 | 25.4 | 31.8 | 4.15 | M3 | 1.2 |

| LK2-C112-M SLK2-C112-M | 12.7 | 28.6 | 38.1 | 5.00 | M4 | 2.5 |

| LK2-C150-M SLK2-C150-M | 15 | 38.1 | 41.3 | 5.90 | M5 | 5 |

| LK2-C200-M SLK2-C200-M | 19 | 50.8 | 51.0 | 6.70 | M6 | 8 |

| Modell | Nenndrehmoment ( N.m ) | Max. Drehmoment ( N.m ) | Max. Drehfrequenz ( rpm ) | Trägheitsmoment ( Kg.m2 ) | Statische Drehsteifigkeit ( N.m / rad ) | Fehler der Exzentrizität ( mm ) | Max. Winkel ( °) | Max. Axialversatz ( mm ) | Gewicht ( g ) |

| LK2-C075-M | 0.5 | 1.0 | 8000 | 9.0×10-7 | 110 | 0.1 | 2.0 | ±0.15 | 13 |

| LK2-C100-M | 1.4 | 2.8 | 6000 | 2.6×10-6 | 170 | 0.1 | 2.0 | ±0.15 | 32 |

| LK2-C112-M | 1.6 | 3.2 | 5000 | 8.9×10-6 | 260 | 0.1 | 2.0 | ±0.15 | 47 |

| LK2-C150-M | 4.2 | 8.4 | 4500 | 3.2×10-5 | 330 | 0.1 | 2.0 | ±0.15 | 94 |

| LK2-C200-M | 9.0 | 18.0 | 4500 | 9.8×10-5 | 560 | 0.1 | 2.0 | ±0.15 | 233 |

| SLK2-C075-M | 1.0 | 2.0 | 8000 | 2.4×10-6 | 230 | 0.1 | 2.0 | ±0.15 | 40 |

| SLK2-C100-M | 2.2 | 4.4 | 6000 | 7.3×10-6 | 320 | 0.1 | 2.0 | ±0.15 | 96 |

| SLK2-C112-M | 3.1 | 6.2 | 5000 | 2.6×10-5 | 790 | 0.1 | 2.0 | ±0.15 | 134 |

| SLK2-C150-M | 7.5 | 15.0 | 4500 | 8.6×10-5 | 980 | 0.1 | 2.0 | ±0.15 | 268 |

| SLK2-C200-M | 14.0 | 28.0 | 4500 | 3.0×10-4 | 1450 | 0.1 | 2.0 | ±0.15 | 392 |

Für weitere Informationen, klicken Sie bitte hier.

Andere Produkte

Anfrageformular

COUP-LINK, Guangzhou LINK Automation Equipment Co.,Ltd.

Add.: 2606-2609 Room, B Building, Feng Xing Square, No.242 Tian He Road, Guangzhou City, Guangdong Province, China

Tel.: 0086-20-3839 5380

Fax.: 0086-20-3839 5480